The life of denim- from start to finish

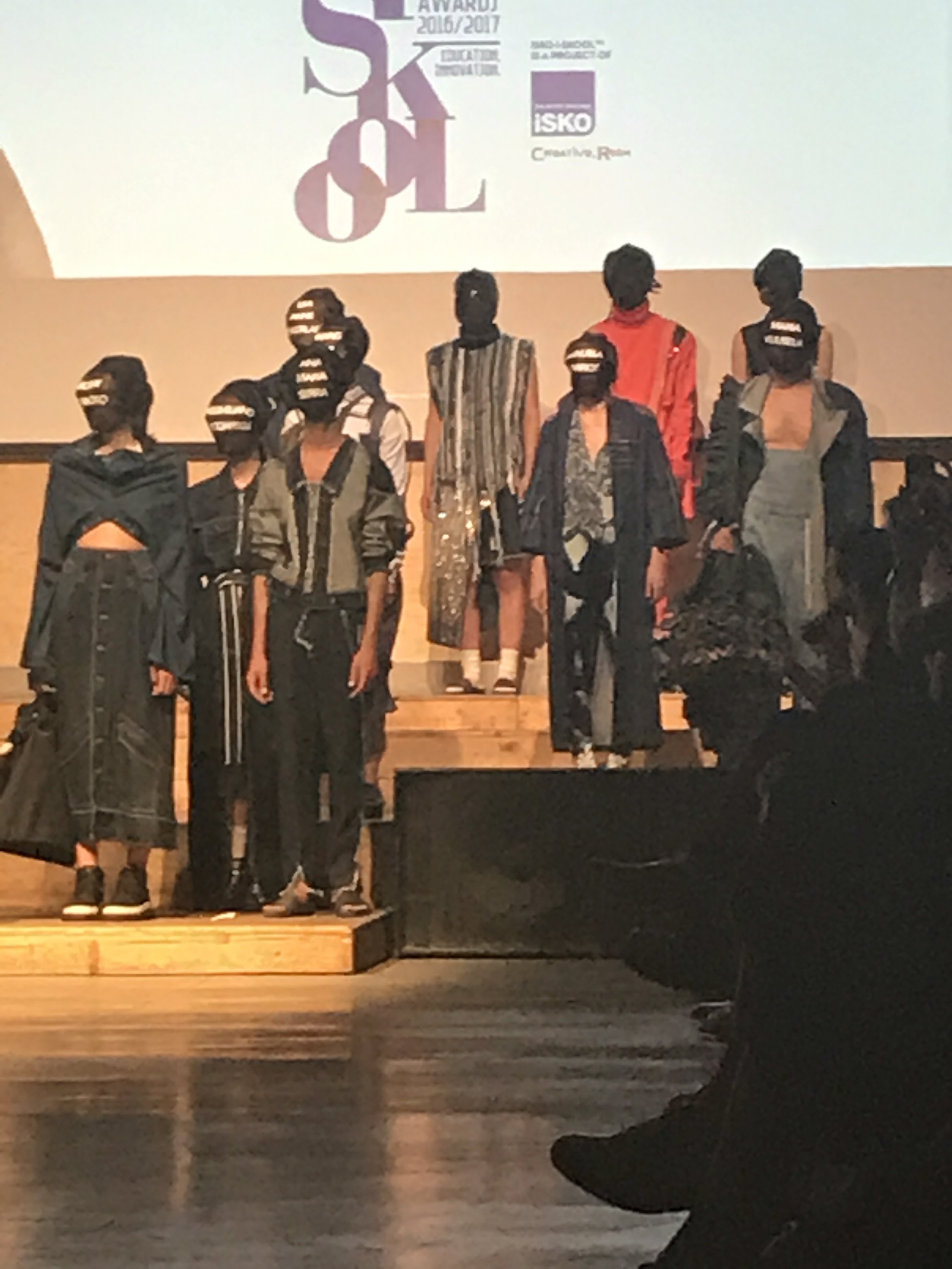

Ever wonder the real secret behind how your jeans that you wear on a daily basis are actually made? Today I got to see each step in the process of making denim thanks to Candiani (a denim mill in Italy), as well as attending the Iskool denim fashion show.

It firs starts off as big bales of cotton, which are grown and transported from cotton farms.

They are then put into long ropes of cotton and stringed along in a machine that will sort them. This is where they can add in any extra fibers if they wanted to have a blend.

The next machine will spin them, which makes them much more thinner. They wrap them around the spools to make it easier to transport it to the next machine.

The next machine is where they add the spandex into the cotton, for the stretch that every jean has. Without this small part, the jean just wouldn't be the same.

The next machine is where the cotton yarn finally becomes a color! They string it along in baths of indigo dye, so they will become the blue jeans we know and love.

Before

After

The next step is to incorporate the warp and weft yarns into the yarn. The warp yarns go up and down, while the weft yarns end up passing in between, creating the fabric.

The next step is to actually have the yarns woven together to make the denim fabric. They take the dyed threads and line them up in a machine that will warp them together. It was cool to see the before and after. Our tour guide said that these selvage machines date back to the 1920's and are rarely found in denim mills any longer. This is where they can be made into different shades of blue, like the light blue, dark blue, or even white!

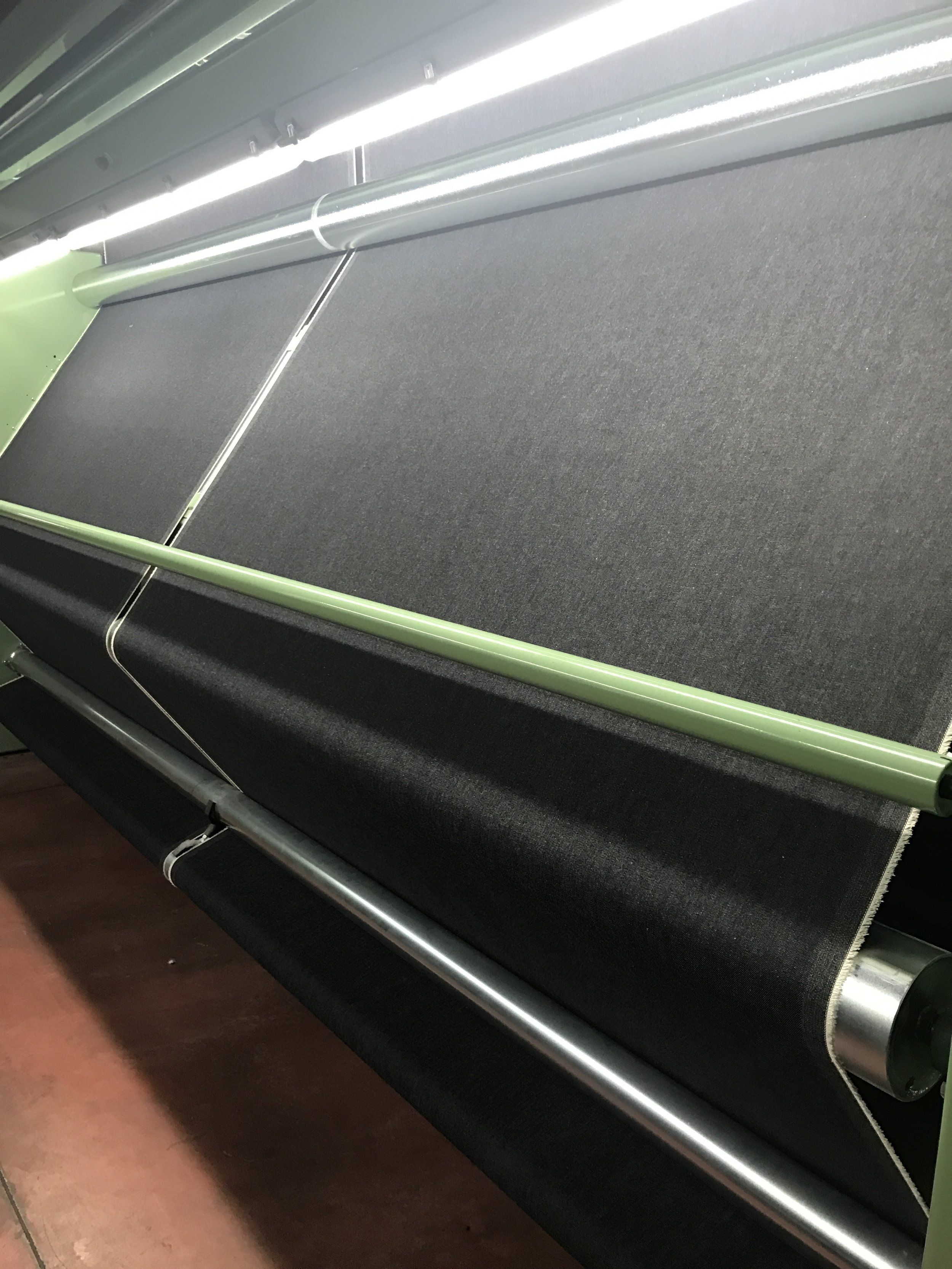

Next comes the inspection, where they have one person looking at any kind of mistake or defect in the fabric. If they see any mistakes, they will stop the machine and circle it with a chalk like crayon, so they know not to add it with the regular denim. They do this for 6 to 8 hours straight, which I think in incredible. They must be seeing denim in their sleep!!!

All of those steps are what goes into each and every jean and denim shirt that you see in stores, on the streets and even on the runway. The denim comes to life with each design and wash. It's crazy how one little piece of fabric can be made into runway material clothing!